The Swap Begins

After gathering parts and planning for months, the time for the swap

has arrived. Actually it was helped along by the recent 750 mile

trip I took in the CRX. About 250 miles out on the return trip, the

little guy started loosing power...down and down the speed went...80...70...60...over

the period of an hour or so. Finally at about 55 MPH top speed, the

bottom dropped out...it would idle, but even flooring the throttle wouldn't

raise the RPM above about 1100. After a few minutes at the side if

the interstate checking it out, I determined that the car had developed

so much blow-by (which gets fed right back into the carb) that it was choking

itself. The quick solution was to pull the lid off the air cleaner...fresh

air coming in from all directions and the car ran pretty good again...back

on the road!!

I put in about 100 miles toward home and the speed started going down

hill again. Again I pulled over...this time to find the paper air

cleaner was on fire and flaming bits were getting sucked into the engine.

I quickly chucked the flaming paper filter, cleaned the crud out of the

carb and hit the road again. Now only 60 miles out, I know the car

is loosing power again, but I'm starting to run out of options...but working

out the loss of power versus the mileage I'm covering, it seems as though

I'll make it home...At 1am, I better, 'cause it doesn't look like anyone

would come get me!

As I pull off the interstate, with only a few miles through town to

go, the car is making a terrible hissing noise, like an air hose

that has blown a fitting, but I know it's just the blow-by. In the

faint glow of the streetlights, I can also see a burnt patch in the hood

paint from the gasses erupting straight out of the fitting on the air cleaner

housing. After nursing the thottle to keep it running through several

stop lights, I finally arrive at home...battered and burnt, but we're home!!

Needless to say, this is the last trip on the old D15...except for the

short trip up the driveway and into the garage. I've got some photos

from the work done in the couple of days after my epic trip...Ill post

more as time allows!

Here we are after the last trip. You will note the burnt spot

on the hood and the lack of air filter assembly. The result of my

"just get the dang thing home one more time" mentality.

The "changing of the guard" so to speak...they meet for the first time.

I don't plan to hot-rod the hell out of the new B, (yeah right!) so hopefully

it will have a long and happy life!

Here we are just getting started pulling the old D engine out.

I got rid of a few things on my last interstate trip...air filter, filter

housing lid, a few hoses...but now it's time to really get a bunch of junk

out of the way. Battery is first, don't want to burn down the rest

of the car! Vacuum boxes, hoses, connections...anything holding the

D to the engine bay. I always take the coolant hoses last...you can

drain oil, you can drain tranny fluid, but you will never get all the coolant

out. Every hose you cut loose drains more coolant out.

Laying in a pool of slimey green stuff to get everything else loose sucks...do

them last and the only thing lying in coolant will be the dead engine!

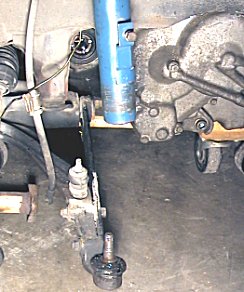

A few hours later...ker-chunk! The old D pukes out on the floor.

Allright...that's more like it...The next day, the 20 pounds of oil-dry

has done it's job on the floor, the engine bay is stripped of most extra

junk, and the "castrol super clean" test has been performed. I tried

out a few squirts followed by some scrubbing (notice the bright red patch

on the upper center of the fire wall) Now this is the cleanest spot

on the car! I just have to do the rest of the compartment.

The old engine is out, but in switching from carburetor to fuel injection,

a few other areas that need attention...do you think I would trust these

crusty gas lines with 40+ PSI of fuel pressure?!? Not a chance...they

will have to go, along with dropping the tank to install a high pressure

fuel pump.

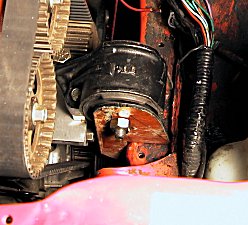

A couple of post-mortem shots on the D. The engine burned so

much oil that the combustion chambers were coated with layers of carbon.

I can just picture the little tips of each flake glowing red while the

engine was running and leading to pre-ignition of the fuel. It killed

the head gasket, and I'm guessing probably killed some piston rings too.

This would account for the large amount of blow-by. Also a quick

look at why CV joints click...they don't seem to like a diet of dirt and

water. I would have fixed this and other problems long ago, but I

knew this engine/drivetrain would be swapped soon anyway. But anyone

with clicking CV joints, take heart...mine clicked away for nearly 30,000

miles...just sounded like rice-crispies every time I turned...snap-crackle-pop!!

Finally, the shot we've been waiting for! Getting the B into

place! I've got several critical measurements to take in order to

make sure the engine is in the chassis straight, square, and true to the

world. Then I'll be able to machine some motor mounts to lock it it..right

now, just a test fit.

Well, I've been held up over the 4th of July weekend and I really got

the shaft on some axles! It turns out that I must have misread some

info...I thought that the 86-89 Acura Integra axles were the ones to use

for this swap, so that's what I ordered up from the salvage yard ($100).

I tore them down completely and rebuilt them with new boots and full synthetic

grease ($50). Then when I tried to put them on the car, they were

WAAAY too long. After taking some measurements, I concluded that

they were more the size of 90-93 Integra shafts. I wound up going

to the local parts store and using these as cores to buy some true 86-89

Shafts which were visibly shorter ($169) but it turns out that they still

don't fit. After going back through all my notes, it appears that

the only shafts that work are the custom shafts from HASport. ($259)

So, it turns out that I am out nearly $580 bucks for friggin' axles...more

than I paid for the motor. I am NOT a happy camper right now, but

I have only myself to blame. The best thing to do would have been

to take the 90-93's back to the salvage yard and trade them for the proper

axles, which I would still have to rebuild with HASport shafts which would

have saved $169...Oh Well...We'll see what happens next week when the axles

get here!

The axles came in about a week ago. Courteous service, prompt

shipping, and a decent product. Those HASport guys are OK!

(Still expensive as hell, though) My only gripe with the axles is

that there is no rust-proofing on the actual shaft. I know they are

lifetime guarantee, but they could at least shoot on some coating like

on the stock axles...nothing like some corrosion pits to make the axles

fail a few years down the road. With the new axles in, I spent the

last week tearing down my new '89 integra shafts, cleaning out the old

"new" grease and rebuilding with synthetic grease and the HASport axles.

With the shafts built, I set out to get the engine aligned. The

first step was to establish some reference point. I put the aluminum

bar across the top of the engine bay, and took measurements from the tips

of the struts sticking through the towers. Now I know the bar is

parallel to the axis of rotation of the front wheels and level with the

frame of the car. The car is on a wheeled floor jack so I can move

the body up and down as well as forward/backward and right/left.

The engine is also setting on a 4 wheeled dolly which allows the fore/back,

right/left movements as well as clockwise/counterclockwise. The final

axis, rotation of the engine (think of holding the axles while the engine

rotates) was handled with some wooden wedges...I found the best fit with

about 6 degrees of rotation (higher in the back)

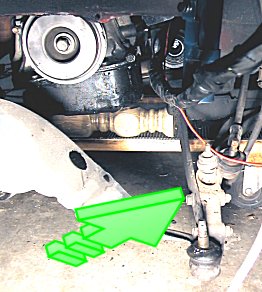

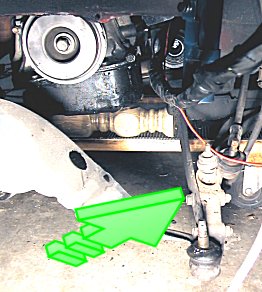

During all my measurements, something just wouldn't line up...I finally

found out that the lower support arm on the drivers side is bent back about

3/4 to 1 inch (green arrow)...must have been damaged before my ownership.

It doesn't show up too well in the pictures, but it's pretty obvious in

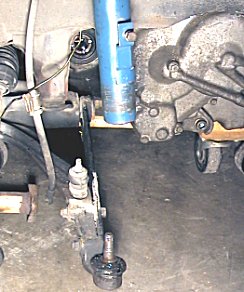

real life! The passenger side (right photo) appears to be OK.

I went ahead and compensated for the bend and set the location of the engine

so I could get some cardboard engine mount templates. When everything

was square to the world. I found that the engine literally has about 1/4

inch clearance on all sides. This automatic tranny is fatter than

the 5 speed!

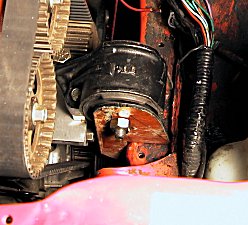

Making some progress toward the engine mounts. This engine came

with the stock rubber mounts. I think they will be sufficient for

suspension of the engine, but I need to link them to the frame somehow.

I wound up machining a new billet aluminum block for the drivers side

mount (center photo) because the mount needed to be located much closer

to the frame rail than the stock cast steel mount. The trans mount

was pretty easy (left photo), it just needed to be boosted up about 1/2

inch, then I wound up cutting a couple of pieces of plate steel (see the

pattern making method here) for both

the trans mount and the new location of the drivers side mount (right photo).

My idea now is to bolt the plates into place, get the engine dead-on located,

then tack weld the plates onto the frame. Once they are tacked, the

engine will be removed one last time (just unbolting the mounts and drop

the engine out the bottom...nothing else is hooked up yet) full weld beads

can then be applied to the mounts.

Well another couple of weeks go by. The motor mounts are

welded. I had another case of the "might-as-wells" when I had to

pull the cast iron exhaust manifold to attach the shift cable. Might

as well put on a new oil pan gasket...while I'm at it, might as well put

on a DC sports header, too! Waiting for those parts has kept me held

up 'till the 5th of August.

The header and the pan gasket finally arrived. I ordered a 4-2-1

header, but a 4-1 got shipped. I'm just ready to get things back

together, so I guess I'll make do. Couldn't bring myself to drill

into the pretty ceramic coating to weld on the O2 sensor bungs, so I'm

going to make an attempt to convert to a 4 wire sensor at the stock location

in the collector...more on that later. Right now, the CRX is getting

ready to take a huge chomp out of a B16!

Getting closer! The engine is actually bolted into place now.

I just have to go around and hook up all of the surrounding connections

(fuel, coolant, electrical, vacuum, throttle, shifter, axles, etc)

Ordinarily, this would only be a minor PITA. But because of the car's

strange new hybrid status every system has to be custom made to mate the

powerplant and car together. One minor issue...I planned for the

engine to sag about 1/8 inch when the engine mounts actually took the weight...it

really dropped about 3/8 inch. I don't think there will be a problem

because I used the rubber mount off of one of the old integra rear trailing

arms for a rear engine mount. It is STIFF! There should not be alot

of monkey-motion in the engine. If there is a problem in the future,

I can simply remove my shims and mill them down about 1/4 inch to get the

engine back on target.

Getting some of the wiring done. I found my self searching for

a home for the ECU and TCU (engine control and transmission control)

Being lazy and not wanting to make two brackets, I pulled the lid off of

both computers and pop riveted them together...now whereever one goes,

the other is along for the ride! Then I had to find a new home for

them. I really wanted to keep the glove box so that was out.

I wanted to keep the space for the radio, too and I didn't want a huge

bulge of wires running under the carpet to put the computers under a seat,

so that was out too. I finally found just the right spot to the right

of the steering column. A space just big enough...almost like it

was made to stuff two computers in. A couple of homemade brackets

later and all is secured!

Spent most of this Saturday finsishing the rebuild on my front brake

calipers. Once those were done I could bolt up everything else...new

tie rod ends, new "custom" axles, Integra spindles with new bearings, etc.

Hopefully everything here will have a long and happy life as it's all new

or totally rebuilt. I also managed to find a company that builds

performance sway bars for front and rear. This may be an upgrade

later in the year!

.